Crack calculation

CSA S6

Code Approach

The equation for the crack width is given in section 8.12.3.2 as

The parameters and depend on the section and the cause of cracking. The code defines in mm as

Where

and is the concrete area excluding the reinforcement. The code gives values for as 0.5 for bending and 1.0 for pure tension. In AdSec we interpolate between these values using

But limited to the range [0.5:1].

The term is taken as the average bar diameter in the tension zone, and the area of steel in is taken as the weighted area of the bar in the tension zone

And the weighting is based on the stress in the bar compared with the stress in the extreme bar.

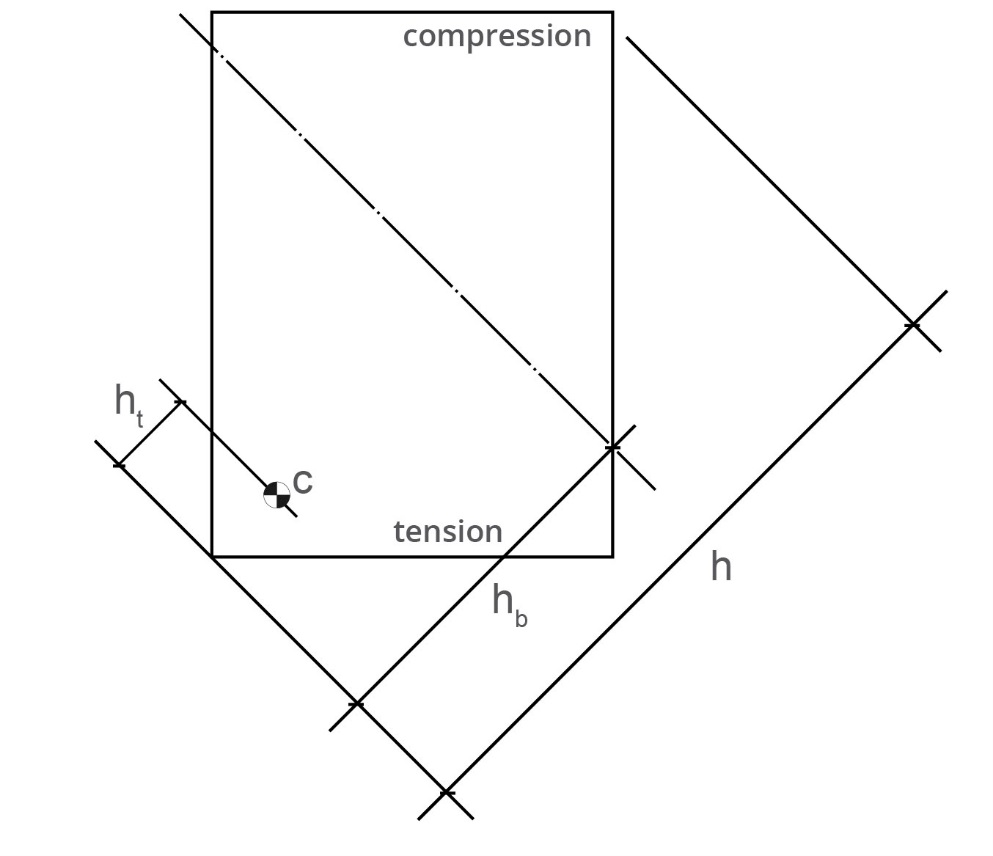

The area of concrete in is

where c is the centroid of reinforcement in tension. The strain term is given in the code as

Where is the stress in the reinforcement at the serviceability limit state and is the stress in the reinforcement at initial cracking. In AdSec this is implemented as

Where is the stress in the most tensile reinforcement at the serviceability for a fully cracked calculation, is the rupture strength of the concrete and is the maximum tensile stress in the concrete at the extreme fibre assuming an uncracked material.

Local Approach

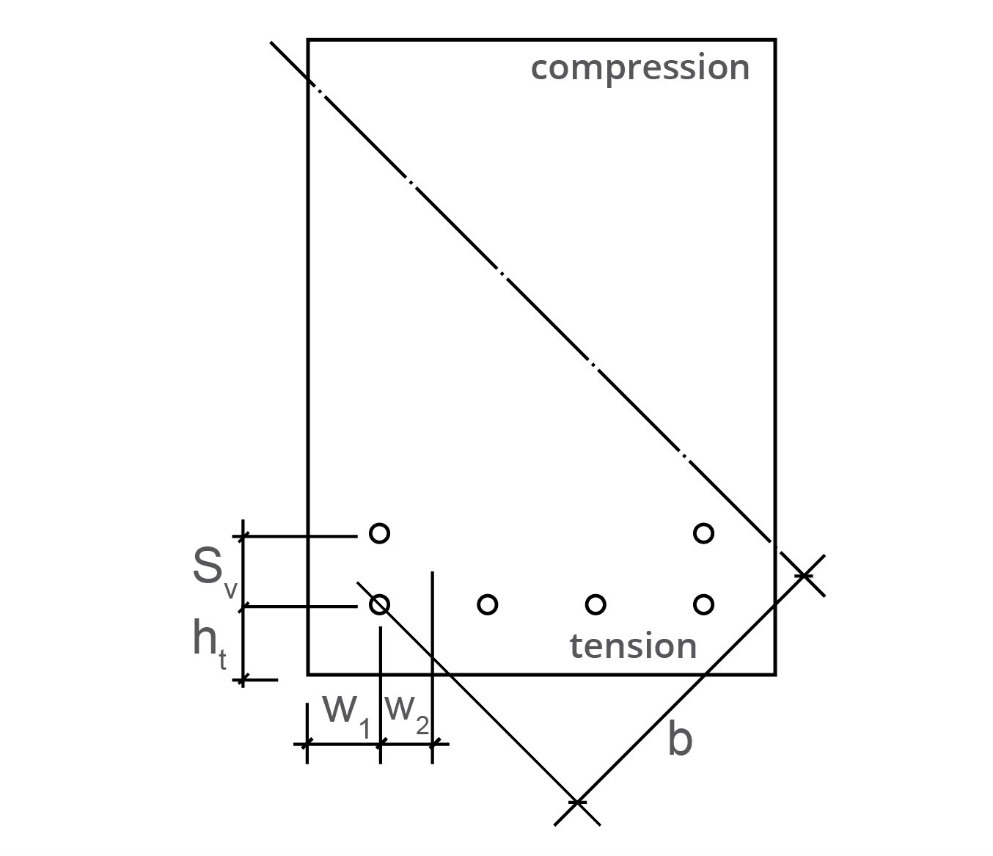

The above approach becomes difficult to justify when the section is not in uniaxial bending. In these cases the alternative local approach can be used. This assumes there is a local relationship between a bar and the surrounding concrete.

The first stage is to identify the most tensile bar and determine the cover to this bar. We then define as the cover plus half the bar diameter.

The depth from the neutral axis the most tensile bar is calculated, and is then defined as

Then the concrete area is based on a dimension

The width associated with this is

So that

EN1992-1

The equation for the crack width is equation 7.8

In this is given by

The code gives values for as 0.8 for high bond bars and 1.6 for plain bars or pre-stressing tendon. The code gives values for as 0.5 for bending and 1.0 for pure tension. In AdSec we interpolate between these values using

But limited to the range [0.5:1]. and are nationally determined parameters which default to 3.4 and 0.425 respectively.

Where the spacing of bar is large, , then

is the ratio of reinforcement to concrete in the cracking zone where the area of concrete is defined as