Element Stiffness

To generate a stiffness matrix for a curvilinear quadrilateral or

triangular element a new approach must be used. Most finite element

codes used an approach based on isoparametric or similar elements.

In an isoparametric element the element displacements are interpolated

in the same way as the geometry, e.g. a plane stress element. In a

superparametric or degenerate isoparametric element the interpolation on

the geometry is of a higher order than the interpolation of the

displacements, e.g. a plate element. In a subparametric element the

interpolation of the geometry is of a lower order than the interpolation

of the displacements, e.g. an eight noded straight sided quadrilateral

element, where a different geometric interpolation function is used for

the geometry from that for the displacements. The term isoparametric is

often used as a general term to cover all these element types.

For a plane stress problem, we can establish a material matrix C that

relates stress and strain. The displacements in a local coordinate

system are

u={u,v} the strains are

ε={εxx,εyy,γxy} and the stresses are

σ={σxx,σyy,τxy} For an elastic-isotropic material the material matrix is

Cp=1−ν2E⎣⎢⎡1νν121−ν⎦⎥⎤ where E,ν are the Young’s modulus and Poisson’s ratio respectively.

Note that there is an out of plane strain εzz, which we

can ignore as it plays no part in the element formulation.

The strains are defined in terms of the displacements as

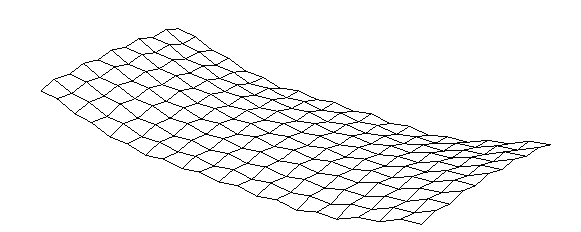

εxx=∂x∂uεyy=∂y∂vγxy=∂y∂u+∂x∂v The simplest elements to consider are the 4 noded and 8 noded

quadrilateral elements, of which the 4 noded element can be considered a

simplification of the 8 noded element. A typical 8 noded element is

shown below. The element has an arbitrary local coordinate system based

on the location of the nodes and the element property axis (x,y), and a

natural (curvilinear) coordinate system (r,s) based on the topology of

the nodes.

We can set up interpolation functions to interpolate the geometry as

follows

xs(r,s)=i∑hixm,i where the hi are the interpolation functions defined below.

These interpolation functions are chosen so that

hi={10}when node is{i=i} As the elements are isoparametric we use the same interpolation function

for the displacements so the displacement in the element is related to

the nodal displacements by

us(r,s)=i∑hium,i To evaluate the stiffness matrix we need the strain-displacement

transformation matrix. The element displacements are obtained in terms

of derivatives of the element displacements with respect to the local

coordinate system (x,y). Because the elements displacements are in the

natural coordinate system (r,s) we need to relate the derivatives in

the local coordinate system to those in the natural coordinate system.

We can write an equation for the derivative with respect to x in terms

of derivatives with respect to (r,s)

∂x∂=∂r∂∂x∂r+∂s∂∂x∂s to establish these derivatives we use the chain rule to set up the

following relationship

[∂r∂∂s∂]=[∂r∂x∂s∂x∂r∂y∂s∂y][∂x∂∂y∂] or in matrix notation

∂r∂=J∂x∂ where J is the Jacobian operator relating natural coordinate

derivatives to local coordinate derivatives. Given that we know x and y

in terms of the interpolation functions the Jacobian operator is easily

found

∂x∂=J−1∂r∂ This requires that the inverse of the Jacobian exist, which requires

that there is a one to one correspondence between natural and local

coordinates. This will be the case provided the element is not grossly

distorted from a square and that it does not fold back on itself.

We can then evaluate

∂x∂u,∂y∂u,∂x∂v,∂y∂v and thus we can construct the strain-displacement transformation matrix,

B

ε=Bu where u is the vector of nodal displacements. The element

stiffness corresponding to the local element degrees of freedom is then

K=∫VBTCBdV The elements of B are functions of the natural coordinate

system, (r,s). Therefore the volume integration extends over the

natural coordinate volume so the volume differential needs to be written

in terms of the natural coordinates

dV=detJdrds The volume integral is not normally amenable to an explicit integration

so normally a numerical integration technique is used. The integral can

be written

K=∬r,sFdrds where

F=BTCBdetJ and the integral is performed in the natural coordinate system of the

element. This is convenient as the limits of the integration are then

±1. The stiffness can then be calculated

K=∑αijFij where the matrix F is evaluated at the Gaussian integration

points (ri,si) and αij are Gaussian

weights.

In a similar way the mass matrix and the load vectors are established.

M=∫VρHTHdV rb=∫VHTfbdV rs=∫SHsTfsdS ri=∫VBTτidV where H is a matrix of interpolation functions and

rb,rs,ri, are the body force

vector, surface force vector and initial stress vector respectively.

Geometric stiffness matrix of shell element

The geometric stiffness matrix is calculated from:

Kg=∫AGTNGdA=∬r,sGTNGdetJdrds where

N=[NxNyxNxyNy] With (Nx,Ny,Nxy) are the in-plane forces of the

shell element in x, y and xy shear directions respectively.

G=[G1G2…Gn] and n is the number of nodes of the elements

Gi=[0000∂x∂hi∂y∂hi000000] 2D Plate Elements

The formulation of 2D plate and shell elements considers both in-plane

and transverse (out-of-plane) displacements. Following Mindlin-Reissner

plate theory, in addition to the bending strains we consider the effect

of transverse shear strain in our complete expression for the element

strain

{γxzγyz}={∂x∂w−βx∂y∂w−βy} where w is the out-of-plane displacement and β is introduced as an

independent variable to express the section rotations (i.e. rotations of

the transverse normals about the local x and y axes).

We can define separate material matrices Cb and

Cs that relate stress and strain for the pure bending and

shear strains respectively and so the pure bending moments and shear

forces can be written

⎩⎪⎨⎪⎧σxxσyyτxy⎭⎪⎬⎪⎫=−zCb⎩⎪⎪⎨⎪⎪⎧∂x∂βx∂y∂βy∂y∂βx+∂x∂βy⎭⎪⎪⎬⎪⎪⎫ and

{τxzτyz}=Cs{∂x∂w−βx∂y∂w−βy} respectively.

In this way we can then express the local element stiffness matrix as a

summation of the in-plane and out-of-plane stiffness’s

K=∫V(BκTCbBκ+BγTCsBγ)dV where Bκ and Bγ represent the

strain-displacement transforms for the bending and shear components

respectively.

While brief, this outlines the basic approach to the Mindlin-Reissner 2D

element stiffness formulation. In GSA we label this concisely as the

Mindlin formulation.

We find that the Mindlin formulation is an effective approach for 2D

parabolic elements where the 8-noded element accommodates sufficient

terms in the stiffness matrix to sufficiently define the behaviour of

the element numerically. However the same formulation defined over a

linear element becomes noticeably more problematic where the absence of

available terms in our 4-noded stiffness matrix leads to numerical

difficulties in expressing the same element behaviour. Specifically we

find a difficulty in attempting to represent the transverse shear strain

terms. Analytically as before we can express the transverse shear strain

as

{γxzγyz}={∂x∂w−βx∂y∂w−βy} although numerically, the difference in the order of terms for the shear

strain may lead to artificial stiffening of the element where the shear

terms are numerically constrained from approaching zero. See reference 1

in the bibliography for further information. This restriction would be

particularly noticeable where the thickness of the plate is small.

A widely practiced remedy is to under-integrate the shear term and while

effective, its use is at the cost of reduced accuracy and stability for

the element. The problem of stability alone is often of greatest concern

where the phenomenon of hourglassing can become apparent in elements

where the thickness to length ratio is large.

An alternative formulation was put forward by Bathe and Dvorkin and has

been found to be especially effective at resolving these difficulties.

The formulation is extendable to higher order elements although we find

the approach is most effective when resolving the difficulties most

apparent in linear elements. The formulation is based upon the theory of

Mixed Interpolated Tensoral Components (MITC). For the pure

displacement-based Mindlin formulation we use the independent variables

wβ=i=1∑nhiTwi=i=1∑nhiTθi where Bathe now introduces a separate independent variable to represent

the transverse shear term

γ=i=1∑nhi∗TγPi We use hi∗ to represent an additional set of

interpolation functions for our new variable γ which we find by a

direct evaluation of the shear strain at points Pi, that is

γPi=(∂x∂w−β)Pi For a linear 2D element we obtain direct values for the shear strain at

four points A, B, C, D on the element and so we evaluate the

displacement and section rotations at these points through direct

interpolation.

We can then construct the interpolations

γrzγsz=21(1+s)γrzA+21(1−s)γrzC=21(1+r)γszD+21(1−r)γszB using direct values for the shear strains obtained at the four points.

This replaces our original expression for the shear terms and we

continue to construct the local stiffness matrix as normal in a similar

approach as before in 2D isoparametric elements. It is lastly worthwhile

to note that the interpolation above assumes our element is in the

isoparametric coordinate system. Further transformations are necessary

to interpolate the shear strains directly through an arbitrary element

in local space. Indeed, when this is done the element shows considerably

improved predicative capabilities for distorted elements.

Element shape functions

The element shape functions for 2D elements are

u(r,s)=i∑hiui These are for the different element shapes

Tri-3

h1h2h3=1−r−s=r=s Quad-4

h1h2h3h4=41(1−r)(1−s)=41(1+r)(1−s)=41(1+r)(1+s)=41(1−r)(1+s) Tri-6

h1h2h3h1h2h3=1−r−s−21h4−21h6=r−21h4−21h5=s−21h5−21h6=4r(1−r−s)=4rs=4s(1−r−s) Quad-8

h1h2h3h4h5h6h7h8=41(1−r)(1−s)−21h5−21h8=41(1+r)(1−s)−21h5−21h6=41(1+r)(1+s)−21h6−21h7=41(1−r)(1+s)−21h7−21h8=41(1−r2)(1−s)=41(1+r)(1−s2)=41(1−r2)(1+s)=41(1−r)(1−s2) 2D Element Shape Checks

A number of element checks are carried out by GSA prior to a GSS

analysis. Other analysis programs may have different limits but the same

principles apply. For GSS the following warnings, severe warnings and

errors are produced.

Triangle

| Warning | Severe warning | Error |

|---|

| 5<rmax≤15 | rmax>15 | |

| 15≤θmin<30 | θmin<15 | |

| 150≤θmax≤165 | | θmax>165 |

Quad

| Warning | Severe warning | Error |

|---|

| 5<rmax≤15 | rmax>15 | |

| 25≤θmin<45 | θmin<25 | |

| 135≤θmax≤155 | | θmax>155 |

| 0.00001<hmax≤0.01 | hmax>0.01 | |

where

rmax longest side / shortest side

θmin minimum angle

θmax maximum angle

hmax distance out of the plane of the element of edge 1 / longest

side

Notes:

The distance out of plane of edge 1 is calculated as hmax

hmax=smaxn⋅(c2−c1) Where n is the element normal, c1, c2

are the coordinates of the first and second corner nodes and smax

is the length of the longest side of the element.

Mid-side node locations not checked but should be approximately halfway

along edge.

No check on ratio thickness/shortest side.

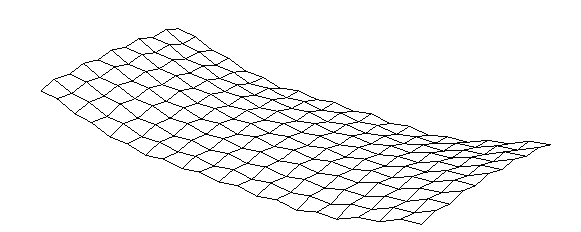

Hourglassing

When Quad 4 elements with the Mindlin formulation are used in bending it

is possible to encounter hourglassing problems. This is a problem that

arises with under-integrated elements where there are insufficient

stiffness terms to fully represent the stiffness of the element. The

problem is noticeable in the results by an hourglass pattern in the mesh

as shown below.

This problem is avoided using the MITC formulation for Quad 4 elements.

This formulation uses a separate interpolation method for the transverse

shear strains and provides considerably greater stability than the

original Mindlin method. The original Mindlin method is kept in GSA for

compatibility with previous models although for new models the MITC

formulation is recommended.

Alternatively when parabolic accuracy is required Quad 8 elements are

recommended. These also formulate elements that are still stiff in all

modes of deformation, even when under-integrated.

3D Element

The element shape functions for 2D elements are

u(r,s,t)=i∑hiui These are for the different element shapes

Tetra-4

h1h2h3h4=81(1−r)(1−s)(1−t)=81(1+r)(1−s)(1−t)=41(1+s)(1−t)=21(1+t) Pyramid-5

h1h2h3h4h5=81(1−r)(1−s)(1−t)=81(1+r)(1−s)(1−t)=81(1+r)(1+s)(1−t)=81(1−r)(1+s)(1−t)=21(1+t) Wedge-6

h1h2h3h4h5h6=81(1−r)(1−s)(1−t)=81(1+r)(1−s)(1−t)=41(1+s)(1−t)=81(1−r)(1−s)(1+t)=81(1+r)(1−s)(1+t)=41(1+s)(1+t) Brick-8

h1h2h3h4h5h6h7h8=81(1−r)(1−s)(1−t)=81(1+r)(1−s)(1−t)=81(1+r)(1+s)(1−t)=81(1−r)(1+s)(1−t)=81(1−r)(1−s)(1+t)=81(1+r)(1−s)(1+t)=81(1+r)(1+s)(1+t)=81(1−r)(1+s)(1+t) The stiffness matrix for brick elements is obtained using selective

reduced integration to alleviate volumetric locking. The

Bˉ approach has been implemented in GSA where the

strain-displacement matrix is split into dilatational and deviatoric

parts7 and then the dilatational part of matrix is replaced with

improved dilatational component. The strain-displacement matrix for

brick elements is given by

B=⎣⎢⎢⎢⎢⎢⎢⎢⎡B1000B3B20B20B30B100B3B2B10⎦⎥⎥⎥⎥⎥⎥⎥⎤ The dilatational and deviatoric parts of the matrix can be computed

using

BdilBdev=⎣⎢⎢⎢⎢⎢⎢⎢⎡B1B1B1000B2B2B2000B3B3B3000⎦⎥⎥⎥⎥⎥⎥⎥⎤=B−Bdil Bˉ is computed using

BˉBˉdil=Bdev+Bˉdil=31⎣⎢⎢⎢⎢⎢⎢⎢⎡Bˉ1Bˉ1Bˉ1000Bˉ2Bˉ2Bˉ2000Bˉ3Bˉ3Bˉ3000⎦⎥⎥⎥⎥⎥⎥⎥⎤ and

Bˉi=∫dΩ∫BidΩi=1,2 and 3 for i=1,2 and 3, and where ∫dΩ is the volume of

the element.

Link Element

Link elements are different to the other element types in that they

apply a constraint between a pair of nodes. The primary node is the

first node specified in the element topology and this is the node that

is retained in the solution. The other node (the constrained node) is

related back to the primary node.

us=Tum The degrees of freedom at the constrained node that are linked will

depend on the type of link. The link allows the constrained node to be

fixed (where the rotations at the constrained node depend on the

rotation of the primary) or pinned (where the rotations at the

constrained node are independent of the rotation of the primary). The

primary node is always has the rotations linked to the rest of the

structure. The links can act in all directions or be restricted to act

in a plane (xy, yz or zx) where the nodes are rigidly connected for

motion in the plane but are independent for out of plane motion.

The constraint conditions are summarised below:

All directions

⎣⎢⎢⎢⎢⎢⎢⎢⎡1000000100000010000−zyδ00z0−x0δ0−yx000δ⎦⎥⎥⎥⎥⎥⎥⎥⎤ where δ=1/0 if fixed / pinned Plane (xy plane as example)

⎣⎢⎢⎢⎢⎢⎢⎢⎡100000010000000000000000000000−yx000δ⎦⎥⎥⎥⎥⎥⎥⎥⎤ where δ=1/0 if fixed / pinned Loads applied to link elements will be correctly transferred to the

primary degree of freedom as a force + moment so no spurious moments

result.

The inertia properties of a link element can be calculated from the

masses at the nodes attached to the rigid element as follows. The mass

is

m=i∑mi and the coordinates of the centre of mass are

xc=m∑imixiyc=m∑imiyizc=m∑imizi The inertia about the global origin is then

Iˉxx=i∑mi(yi2+zi2)Iˉxy=−i∑mixiyiIˉyy=i∑mi(zi2+xi2)Iˉyz=−i∑miyiziIˉzz=i∑mi(xi2+yi2)Iˉzx=−i∑mizixi and relative to the centre of mass (xc,yc,zc) this is

Ixx=i∑mi((yi−yc)2+(zi−zc)2)Iˉxy=−i∑mi(xi−xc)(yi−yc)Iyy=i∑mi((zi−zc)2+(xi−xc)2)Iˉyz=−i∑mi(yi−yc)(zi−zc)Izz=i∑mi((xi−xc)2+(yi−yc)2)Iˉzx=−i∑mi(zi−zc)(xi−xc) The constraint equations for a link element assume small displacements.

When large displacements are applied to a link element the constraint

equations no longer apply and the links between constrained and primary

get stretched. This effect can be noticeable in a dynamic analysis where

the results are scaled to an artificially large value. When these are

scaled to realistic value this error should be insignificant.

7 Hughes T. J. R. The Finite Element Method – Linear Static and Dynamic Finite Element Analysis, Dover, 2000